|

|

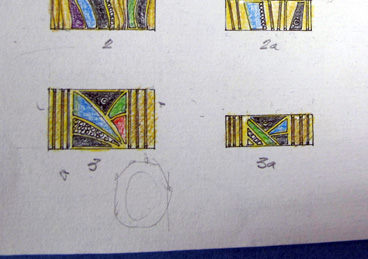

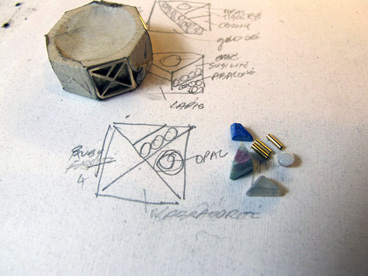

1. Sketch for the proposed rings. After discussion with the client, sketches are produced. After consultation, more sketches are created or a wax model is made. |

| |

|

|

|

|

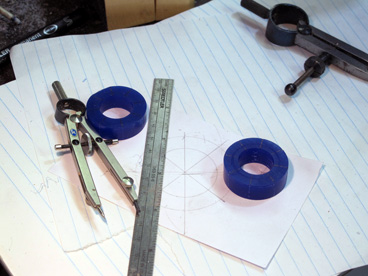

2. Layout of the design in the wax. |

| |

|

|

|

|

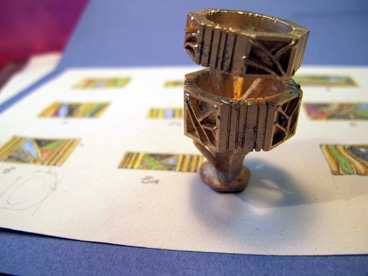

3. Carving the wax model. The wax model is the 3-dimensional interpretation of the sketch and therefore can be tried on and fitted much like the final ring. This is an important step as it also allows the client to make changes or refinements, ensuring satisfaction with the design. |

| |

|

|

|

|

4. Finished wax models. After approval by the client, the wax models are resolved and finished, ready for casting. As these rings will have inlays in some of the surfaces of the ring, the partitions or walls separating the inlay areas are put in with a different wax (pink). Refinement of these design areas will happen after casting.

The rings will be made by the ‘lost wax process’, in which the rings will be imbedded in a plaster-like ‘investment’, slowly heated in a kiln over several hours until the wax has burned away and the investment properly cured.

The wax wires, or ‘sprues’ (red) supporting the wax rings create a path which allows the wax to escape the mould and for the molten metal to enter. |

| |

|

|

|

|

5. Pouring in the investment around the wax ring model. |

| |

|

|

|

|

6. These rings will be made in 18K gold, which is 75% fine or pure gold and the remaining 25% an alloy or mixture of copper and silver. |

| |

|

|

|

|

7. The burn out in the kiln takes place over several hours during which the wax will be completely burned away and the investment cured. |

| |

|

|

|

|

8. Melting the gold in a ceramic crucible. This casting method uses a centrifuge which spins at a high speed forcing the molten metal into the mould, filling all the cavities left by the wax. |

| |

|

|

|

|

9. The finished casting. The sprues will be cut off and the rings finished by filing off the excess metal, sanding and finally polishing. |

| |

|

|

|

|

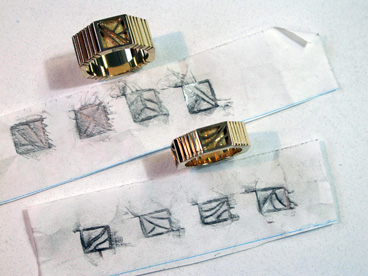

10. A rubbing gives the patterns necessary to cut the various inlay materials. |

| |

|

|

|

|

11. The patterns are glued onto the inlay materials which are then cut to fit into the small cavities on the surface of the ring. |

| |

|

|

|

|

12. Inlay materials all ready to be inlaid into the ring. Tape covers the other areas of the ring to keep the polished surface clean. |

| |

|

|

|

|

13. Epoxy glue is dyed to closely match the colour of the inlay materials. After the epoxy has cured, the excess material is ground off and the inlaid surface is polished. |

| |

|

|

|

|

14. The finished rings. |